Our manufacturing capabilities include the design and implementation of integrated production processes for both semi-finished and finished products ready to enter the end market. We are able to manage and quickly adapt to both mass production needs and individual series and prototypes.

Our manufacturing capabilities include the design and implementation of integrated production processes for both semi-finished and finished products ready to enter the end market. We are able to manage and quickly adapt to both mass production needs and individual series and prototypes.

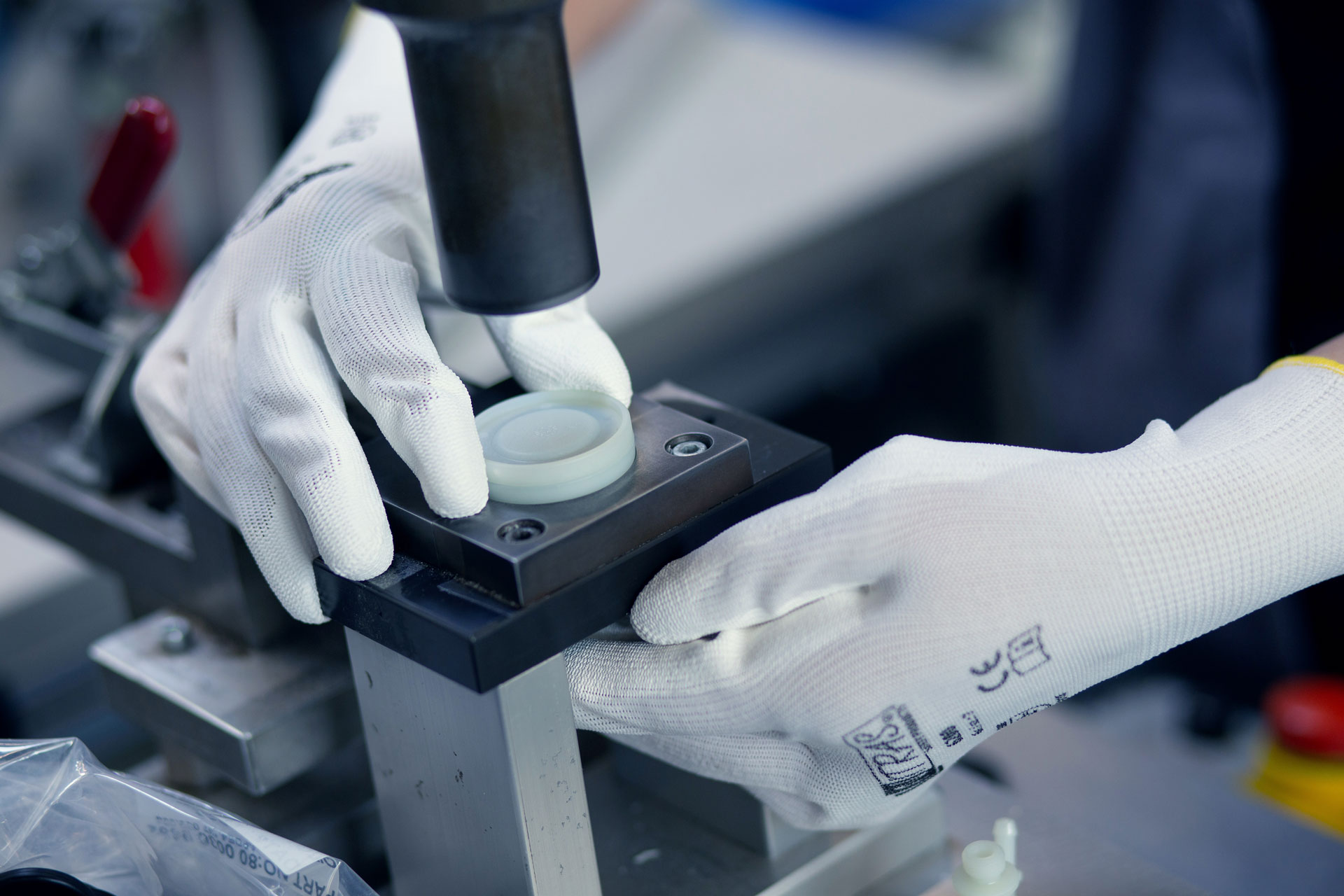

Production processes are the result of our own development and knowledge.

The close cooperation with our development team (link to development) enables us to symmetrically upgrade and coordinate production processes on both sides, so that they meet all technical and developmental conditions of production. Key production advantages:

- Management of technically demanding production processes

- Rapid response

- Flexibility of production capacities

OVER 11,000 m2 OF USABLE AREA We have over 11,000 m2 of usable area of universal production infrastructure for the manufacture of a wide range of products for a wide range of industries.

Modern technological equipment and tools enable us to perform technically demanding products.

Our competences: